AI-Driven Supply Chains at Scale

Global supply chains are under pressure. From climate events to labor shortages, companies need faster, more flexible tools to plan and respond.

One of Blue Yonder’s Supply Chain applications, originally built in C++ on Oracle in the 1990s, wasn’t keeping up. It was hard to maintain, slow to scale, and didn’t support modern supply chain complexity or sustainability goals.

At the same time, their customers were asking for:

Better real-time planning

Easier scenario simulations

More sustainable decision-making

Lower operational costs

Blue Yonder needed a smarter, leaner solution—fast.

The Solution: A Modern System Built on AI and Graphs

Blue Yonder chose Snowflake and RelationalAI to power the next generation of its platform.

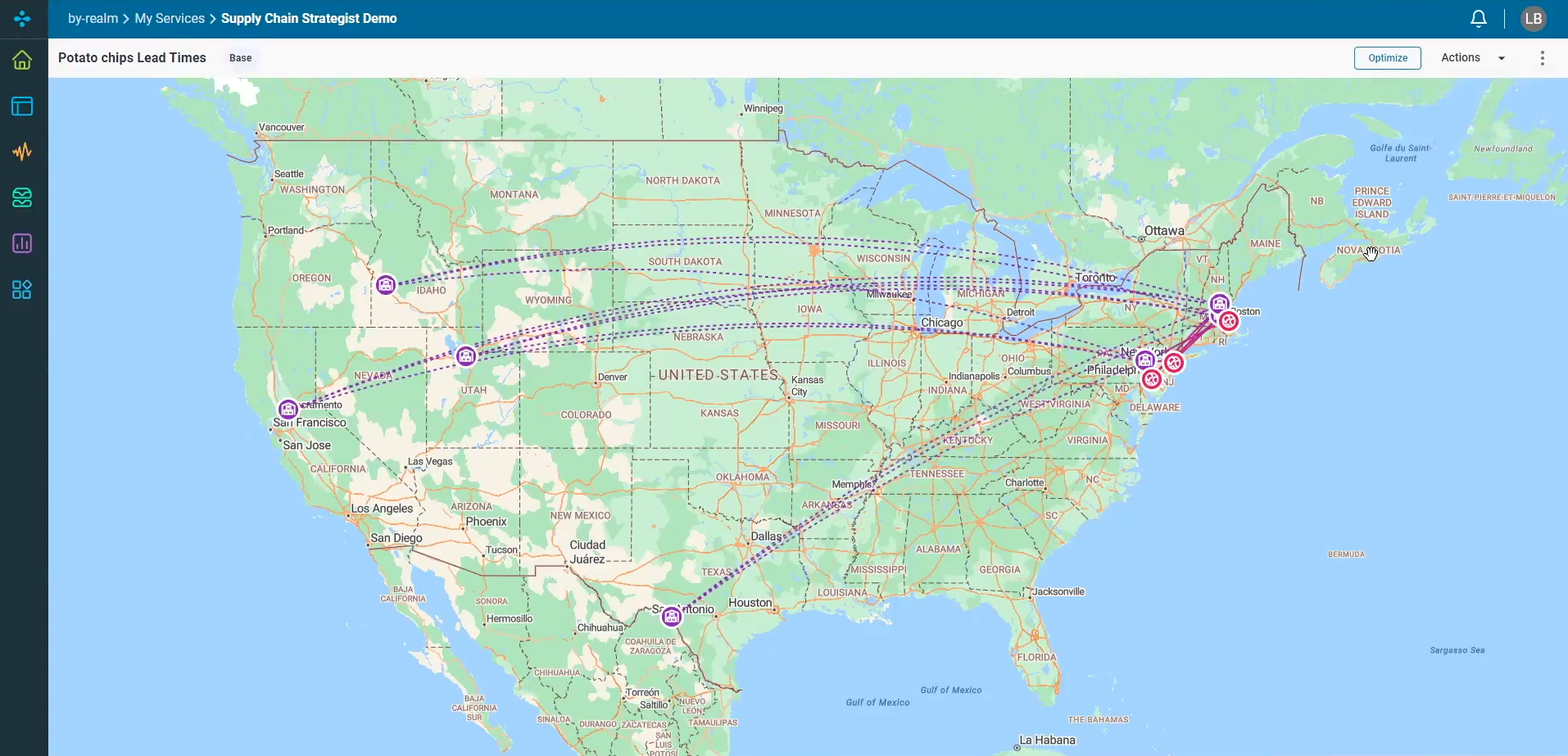

Using graph reasoning, they built a centralized knowledge graph to represent complex supply chain relationships—like product-to-supplier-to-store networks. This made it easier to understand and optimize these relationships with real-world constraints.

They replaced a massive 205,000-line C++ codebase with just 8,500 lines of SQL and rule-based logic, a 20x reduction. The entire system was moved from desktop to cloud-native, running securely within Snowflake.

“The transition to a cloud-native solution has revolutionized our supply chain management capabilities.”

—Amanpreet Singh, CVP, Greenfield Innovations, Blue Yonder

AI Workloads Driving the System

RelationalAI brought multiple layers of intelligence to the new platform:

Prescriptive reasoning to recommend optimal actions

Rule-based reasoning to encode business logic and constraints

Graph reasoning to map and query complex networks

Predictive reasoning to simulate demand and disruption scenarios

This combination enabled what-if analysis. For example, if a snowstorm shut down a warehouse, users could simulate the impact and re-optimize routes instantly—minimizing costs, delays, and stockouts.

“You can see the difference between scenarios side by side—cost, fulfillment, service level. That’s the power of this solution.”

—Amanpreet Singh

The Results: Faster, Leaner, Smarter Supply Chains

✅ 20x smaller codebase

✅ 50% reduction in total cost of ownership

✅ 10x scalability boost

✅ Completed in weeks

✅ Enabled real-time, scenario-based decision-making

“It’s the fastest modernization we’ve ever done—without a single person supporting the old code.”

—Amanpreet Singh

The results didn’t just help Blue Yonder—they helped their customers, who can now balance cost, service levels, and sustainability goals in every supply chain decision.

A Strategic Edge for the Future

CEO Duncan Angove called the knowledge graph approach “perfectly oriented to supply chains,” because “they’re all about relationships—between product, brand, supply, and store.” With AI-powered decision-making built in, Blue Yonder has redefined what modern supply chain platforms can do.

“For agents and language models, this brings critical context and semantic meaning to the data.”

—Duncan Angove, CEO, Blue Yonder

Project Information

Customer

Blue Yonder

Category

Tech, Retail, Supply Chain

Applications

Supply chain network optimization

What-if scenario simulation

Sustainability-driven decision support

Modernization of Supply Chain Strategist (SCS)